- a bellows with a wide distance between the rail and the lens mount (the mount can not be in between the handles)

- two brackets about as wide as the bellows

- 2 1/4 inch- 20 screws with course thread

- 4 small screws to attach the brackets to the bellows

- a iron saw and a round file

- 2 small ball heads ( I got mine from B&H for $10 a piece)

Sunday, March 30, 2008

Self-made tilt shift bellows

Monday, March 10, 2008

Home made photo equipment at dpreview

http://forums.dpreview.com/forums/read.asp?forum=1036&message=22992716

The Door Knob Palm Rest

You need a door knob, a plastic washer and a screw with course thread (I don't remember the diameter- sorry). Saw the head of the screw off, and wrap it with scotch tape that it just fits in the hole of the door knob, fix it with the screws on the knob. Get the shortest knob you can find, the one I used in the picture is quite long, I would prefer it about 1cm shorter.

Hacking a Pentax K teleconverter to an A

The only thing a lens (or converter) needs to be recognized as A is the contact which tells the camera that the aperture ring is in the A position (indicated as 'A' here:http://www.robertstech.com/matrix.htm). On an A-lens this contact gets retracted when the aperture is in any other position than A - but for my purposes always on is just fine. So the only task is to build this contact.

I did this with a little metal ball (from a ball bearing). I drilled a hole in the bayonet of the converter which was about 3/4 of the size of the ball, than I made it conical by grinding it out with a small phillips screwdriver and a larger drill (the bayonets metal is really soft) so that the ball fits in. The ball has to protrude about 0.2mm. To find the right spot I used the bayonet of an old a 2.0 50mm A lens as mask. The A bayonet, by the way, fits the converter without further modifications but I did not have the contact on this one any more (to make this contact fit you would still have to make some space on the converter itself).

The A contact has to be spring loaded since it needs to be pushed back when the converter is mounted on the camera. To do this I had to make some space on the converter, I drilled a hole in the converter at the position where the A contact will be (see picture). First I wanted to use a little piece of latex foam as spring but I found a real spring which had just the right size. When I put it together I did not put the black ring back into the converter which tells the camera which aperture is set on the lens. None of the digital cameras can read that setting and it was in the way of the spring.

I put the converter on the camera- and it recogniced it as an A lens the aperture was displayed on the display and I can set it with the wheel on the camera.

Without further modifications the converter is recognized as an f1.2 lens, meaning that the wide open aperture displayed on the camera is 1.2. This does not affect the metering in any way (since it is TTL) you just have to keep in mind that 1.2 is wide open, 2.4 one step down and so on. This can be a bit confusing and it is easy to tell the camera the maximum opening of the lens.

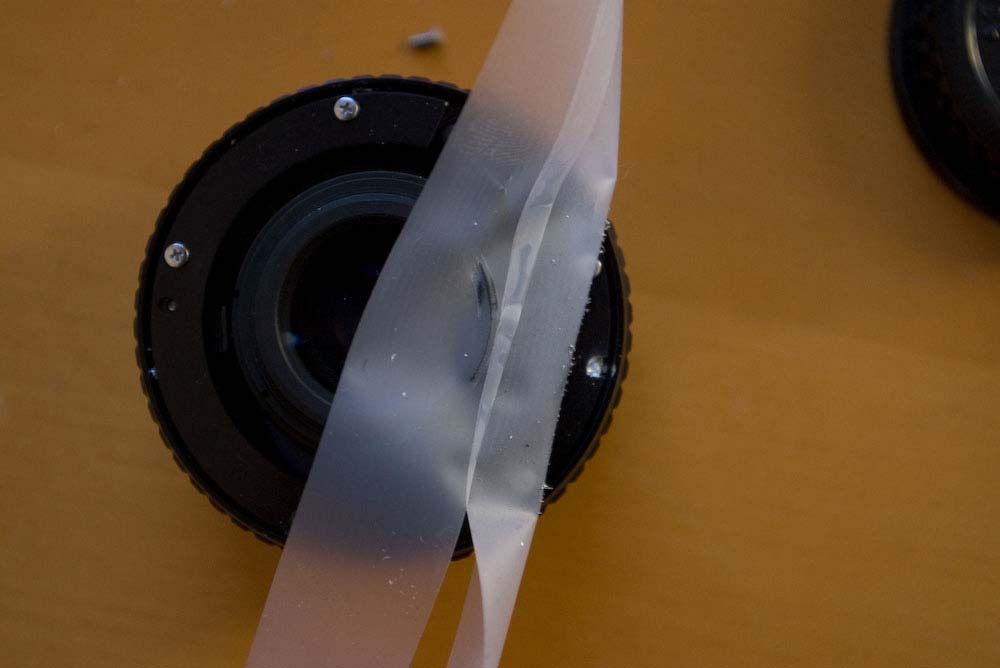

Here the converter with the contact. I made one of the insulators with nail stain the rest is scotch tape.

No- it has to be an A lens. With most of the older non-A lenses the aperture closure is not linear and can not be controlled by the camera. That is why you can not modify your M lens to be an A lens. If you want to test if your M lens works anyway just put a little piece of aluminum foil on the A contact of the camera bayonet to build the contact and see it it stops down correctly (be really careful not so jam anything with the foil, though).